Formula Foundry software

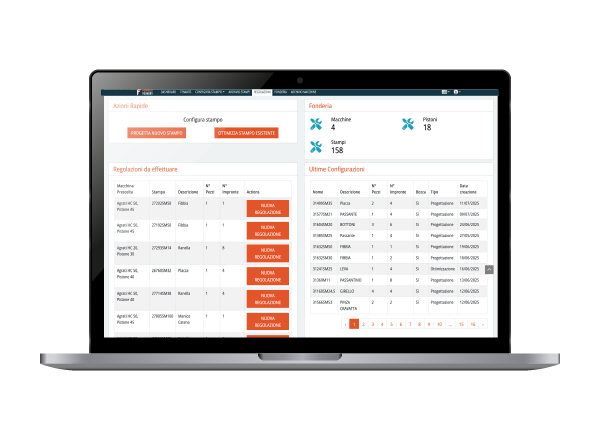

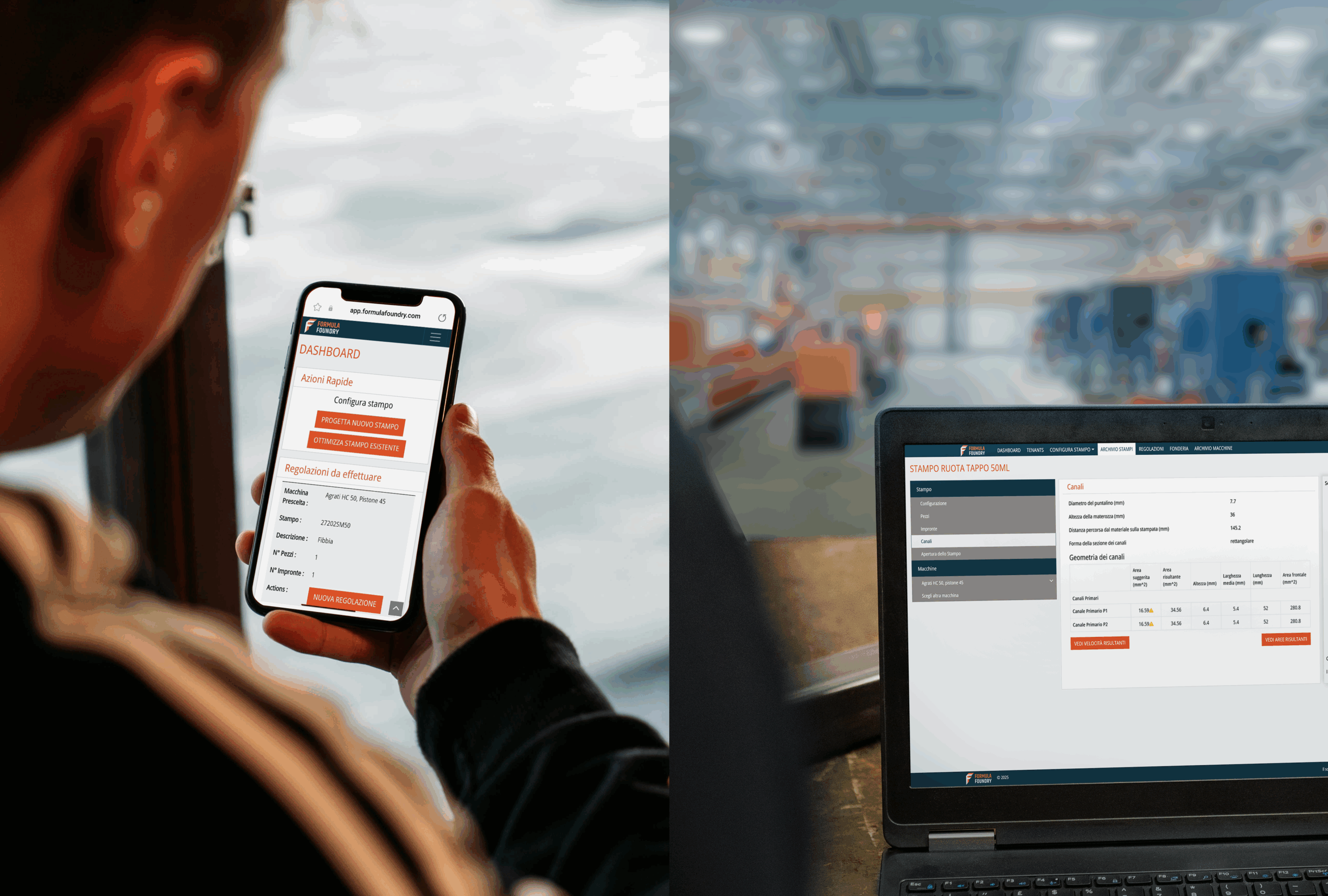

Formula Foundry is the first software specifically designed for the scientific management of the die casting process. Based on a patented method and developed directly in the foundry, the software allows users to analyze, optimize and monitor the critical parameters of each shot, turning field experience into solid data and measurable corrective actions.

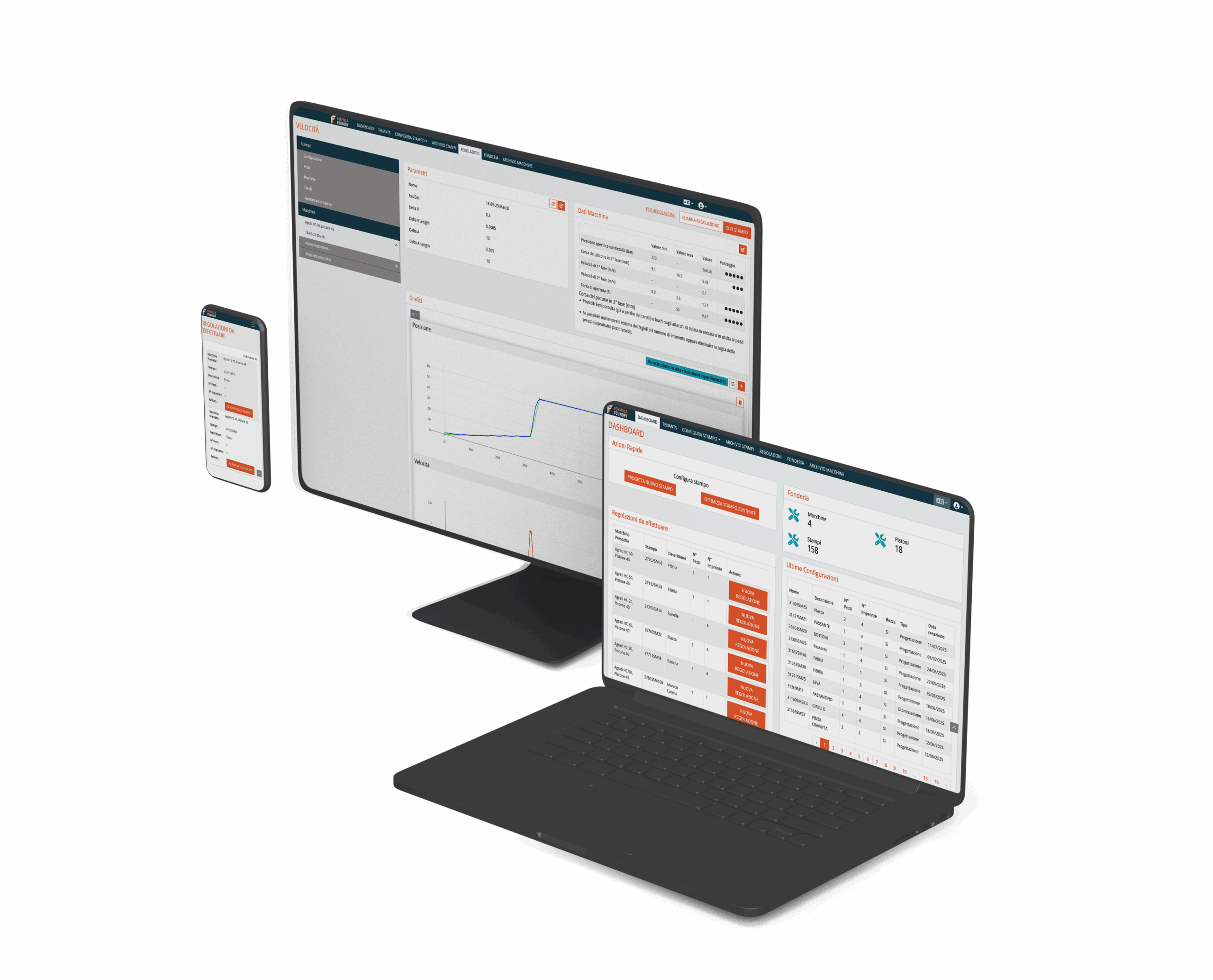

Through an intuitive interface and integrated analysis tools, Formula Foundry enables precise control over the injection phase, improving process stability, reducing scrap, and increasing positive repeatability.

The software is designed to easily integrate into existing production environments, working with real machine data and communicating with the tools already in place in the foundry. Its goal is to provide a practical, fast and reliable tool for making more effective operational decisions.